Product Manufacturing Process

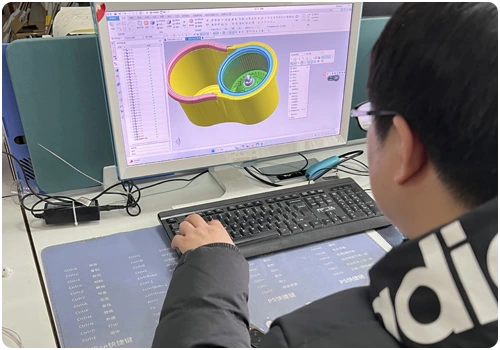

Moulding Design and Drawing

The birth of a mop starts with its design. Focusing on the practicality and aesthetics of the product, and use professional design software, our designers create the mold drawings for the cleaning mop.

3D Printed Sample Testing

After the product drawings are completed, they cannot be immediately put into production. Instead, they enter a crucial stage, which is sample testing. Our designers input the drawings of this cleaning mop into a 3D printer and use it to print all the plastic components. Subsequently, the assembled samples undergo a series of performance tests.

CNC Moulding Processing

Upon passing the sample performance tests, the mold drawings for this mop are transferred to the CNC mold processing workshop for injection mold processing.

Plastic Injection Production

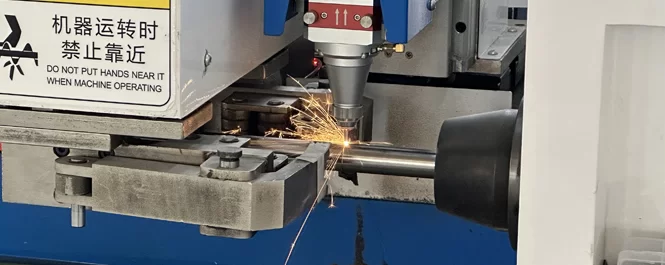

Stainless Steel Poles Welding

Mop Microfiber Textile

Once the injection molds are produced, they are delivered to the injection molding workshop, where they are installed into various types of injection molding machines. Using selected 100% all new plastic raw materials, the injection molding workshop commences large-scale production of plastic parts. These plastic components produced by injection molding are then packed into semi-finished plastic storage boxes to ensure cleanliness and tidiness.

Simultaneously, other components used in the mop begin production. The stainless steel pipe manufacturing workshop initiates welding and cutting to produce suitable stainless steel pipes, while the mop head textile workshop spins and produces microfiber mop heads out.

Production Line Assemble and Packaging

Once all the components of the mop are manufactured, they enter the assembly line. Equipped with ten production lines and manned by dozens of experienced workers, they carry out the final assembly and packaging of the products under the quality inspection of the QC department.

The packaged products are then sent to the finished product warehouse and await delivery to customers.