We care about every step of your order production

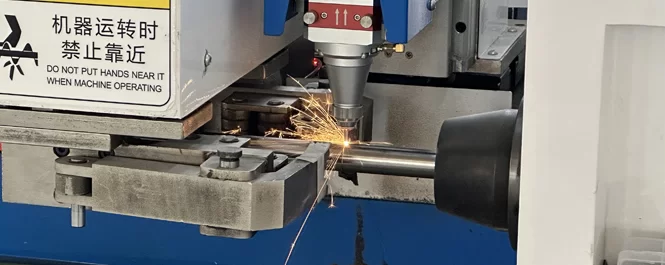

From the birth of a household cleaning mop to its delivery to end customers for use, it undergoes many processes. For example, injection molding, welding and cutting of stainless steel pipes, production of mop heads, and finally, assembly and packaging on the assembly line. Take our RLT series sponge mop as an example. Before final assembly and packaging on the assembly line, our production workshop will produce various parts needed for the RLT sponge mop, including plastic parts, stainless steel pipes, and mop heads. These parts cannot be immediately put into assembly and packaging on the assembly line after production; instead, they are placed for a period of time. On one hand, it’s necessary to wait for all the parts to be ready before they can be fully put into the assembly line; on the other hand, these parts need to undergo random quality checks by the QC department before they can go online for assembly. If these parts, especially the plastic ones, are casually placed on the warehouse floor and exposed to the air, they will accumulate some dust due to static electricity and other factors. We can see how static electricity works through some science tricks using static electricity>>.

To deliver the clean and neat products to you and your end customers, how do we do it?

We designd and manufactured more than 2 thousands plastic storage boxes to store the plastic parts of the mop.

The key advantages of using plasitc to contain the semi-finished plastic parts:

> Keep dust away from the surface of products, make sure deliver clean and neat products to customers.

> Make production process more orderly, better warehouse management.

> More conductive to products quality control.

When the plastic parts are produced from the injection molding machine, they are directly placed into clean plastic storage boxes and covered with lids for storage, awaiting random quality checks by the QC department and entry into the assembly line for assembly and packaging. Such a process ensures that the parts of the product are not contaminated by dust. When customers receive this mop, it shines as new, enhancing their experience and satisfaction. We focus on product quality and every aspect of production, all to better deliver your orders.